As global energy needs are increasing and renewable energy systems become more common, energy storage is becoming a pivotal component in the global energy landscape. Current research being conducted in our lab includes a techno-economic analysis of various energy storage technologies including lithium ion (Li-ion) batteries, sodium-sulfur batteries, lead-acid batteries, flow batteries, super capacitor, superconducting magnetic, thermal, flywheel, pumped -hydro, and compressed air. Applications are targeted at demand-side management in industrial facilities.

One of the most promising solutions for reliable energy storage is Li-ion batteries. Through optimizing the charging and discharging of battery energy storage an industrial facility can achieve savings by reducing peak demand and shifting its energy usage from on-peak hours to off-peak hours.

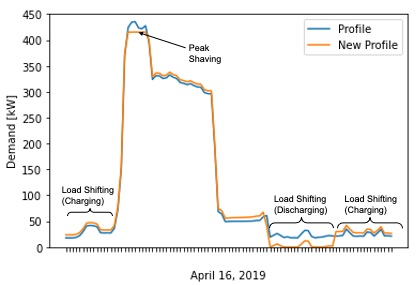

An energy storage dispatch optimization model was developed to simulate peak clipping and load shifting control strategies of the energy storage system to maximize cost savings for industrial facility owners. Many different sized energy systems are tested with various discharge durations to find optimally sized energy storage systems for demand response applications.

—

Due to the multitude of energy storage systems and their respective performance parameters, a Matlab teaching application was developed to help students effectively learn:

- Operational differences of energy storage systems for intermittent and continuous process industrial facilities

- Performance differences between energy storage systems

- How the use of energy storage systems result in flatter demand profiles

This tool is available for use by downloading the following zipped folder (containing the user guide, quiz, quiz solutions, survey, and Matlab application installer file):

As this is an ongoing research project, please send back the survey and feedback to [email protected] for assessment of the teaching efficacy of the software tool.