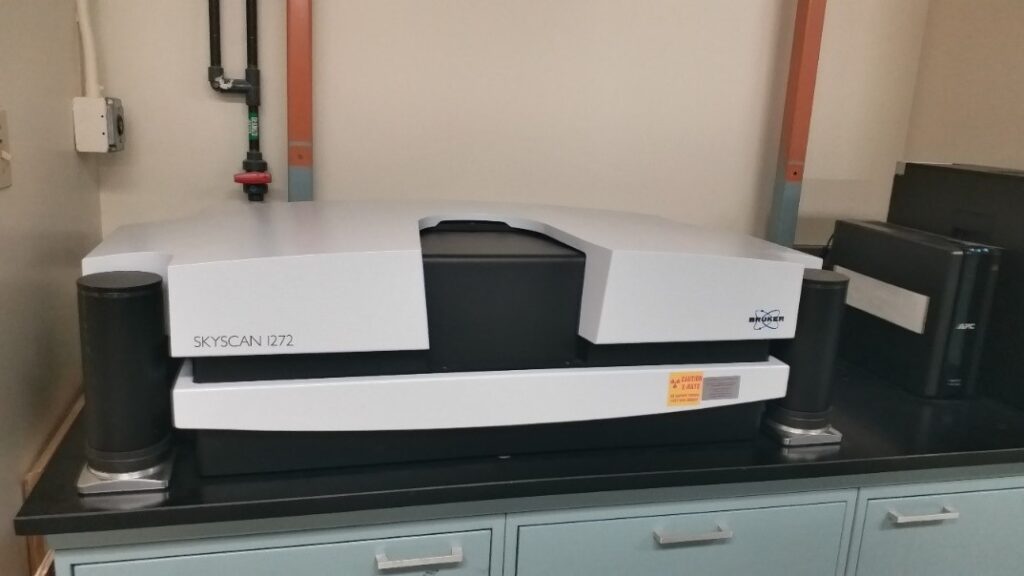

MiCro CT system- Skyscan 1272

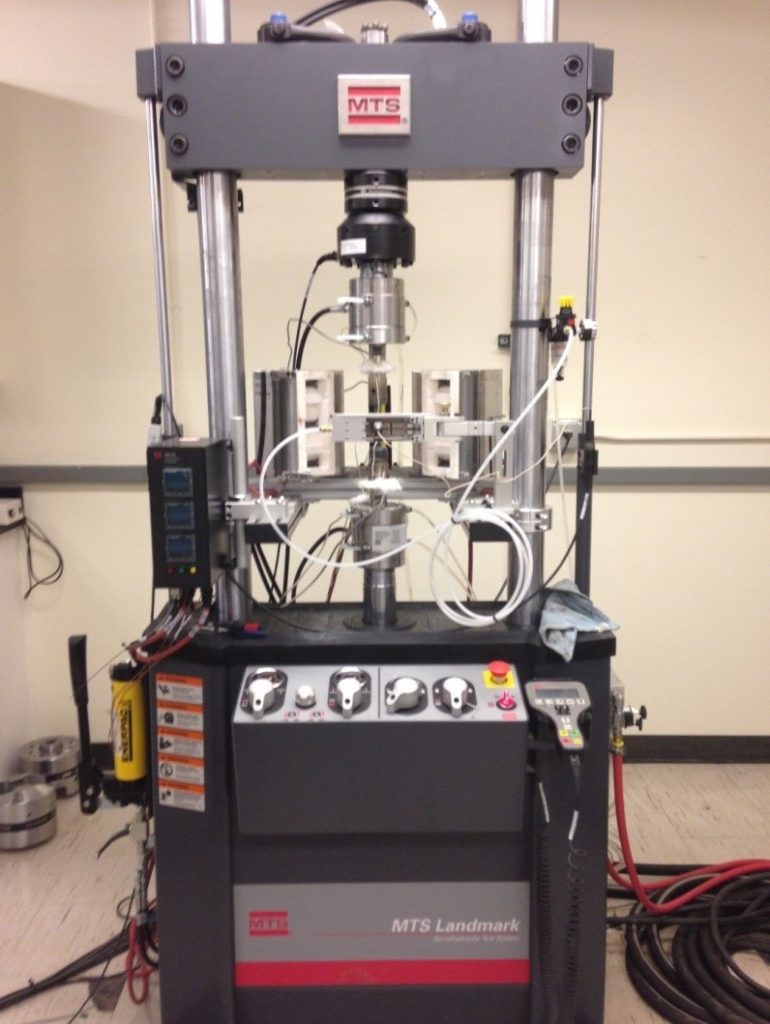

MTS Landmark ® Servohydraulic Test Systems

100 kN with various standard and in house grips equipped with high temperature creep fatigue testing system up to 1000 degree C equipped with digital image correlation system for con-contact strain measurements

10 kN MTS electron-mechanical testing machine

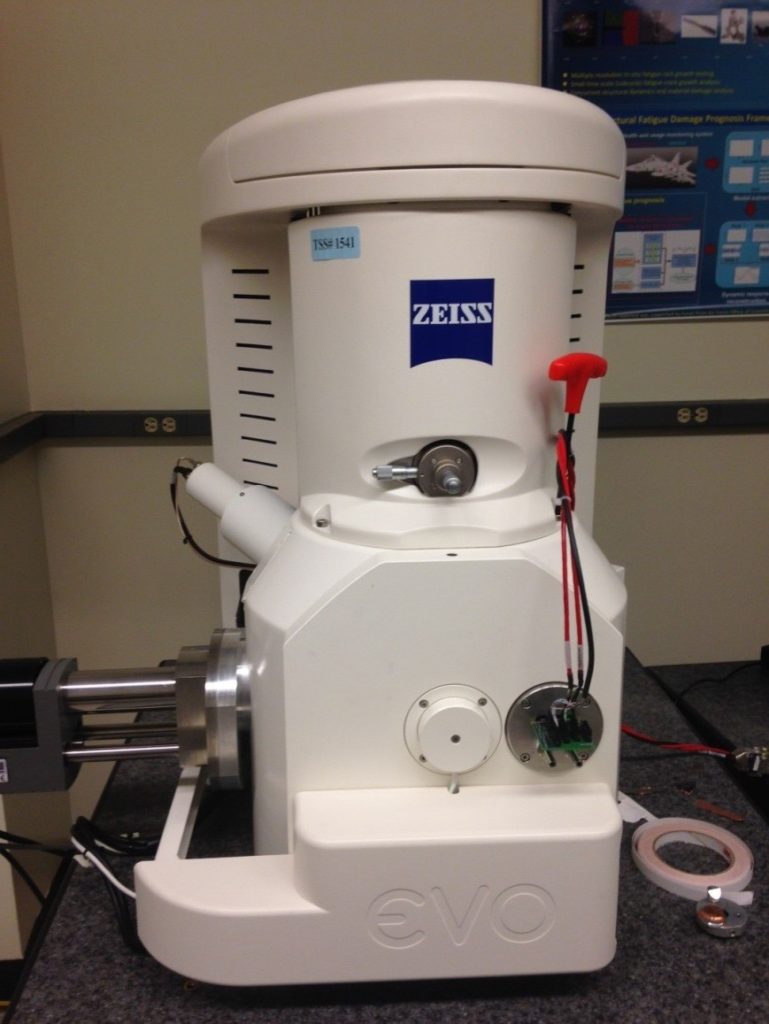

Zeiss EVO scanning electron microscope

Work with tensile stage for both in situ and ex situ measurements Gold coater for composite and polymer imaging

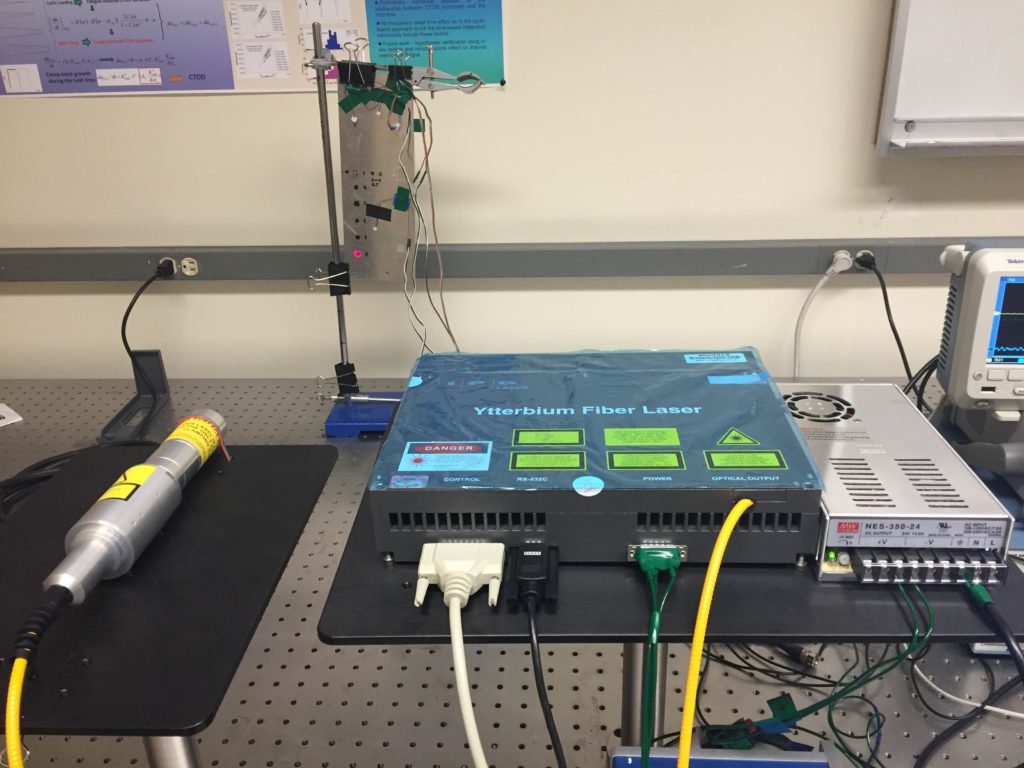

High power (20w), fast (1~2 ns) MOPA laser source and controller

Laser-ultrasound / optoacoustic generator

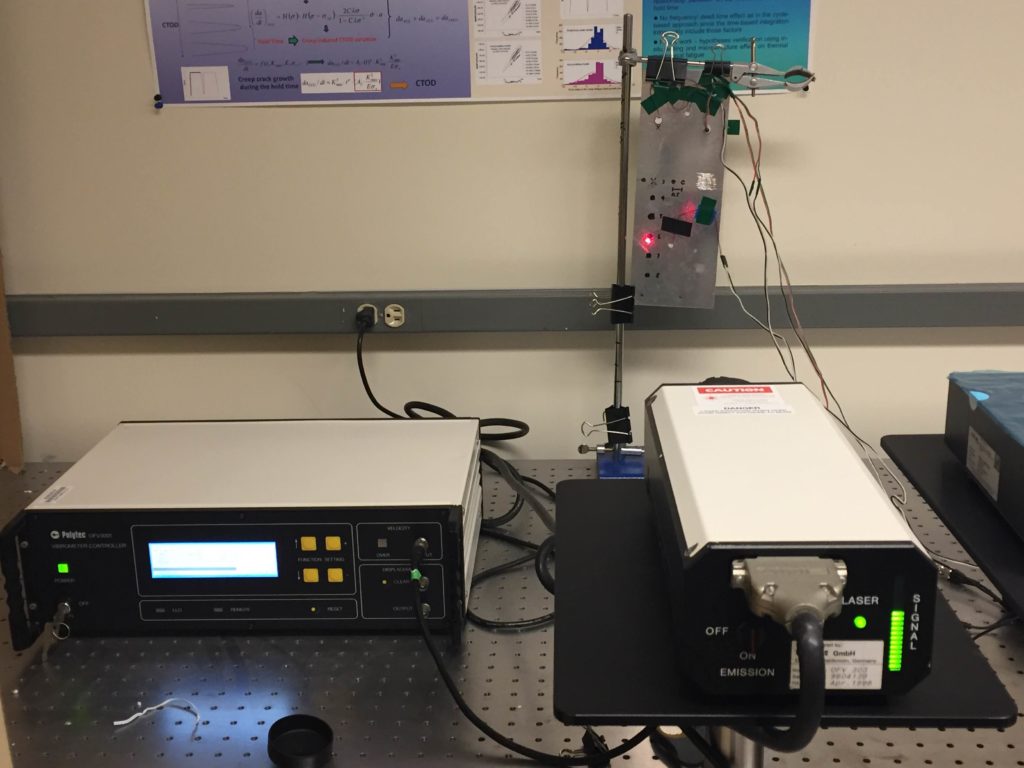

Laservibrometer for non-contact vibration and wave propogation measurments

FLIR high resolution thermal camera for real time temperature field measurments

Current setup for SONIC IR and Laser pulse IR imaging

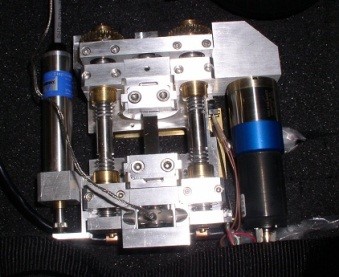

In situ mechanical tester with complete controller and grips for tension, compression, bending static and fatigue loading

Upto 5 kN loading, under optical microscope and SEM with high temperature heating upto 1000 degree C

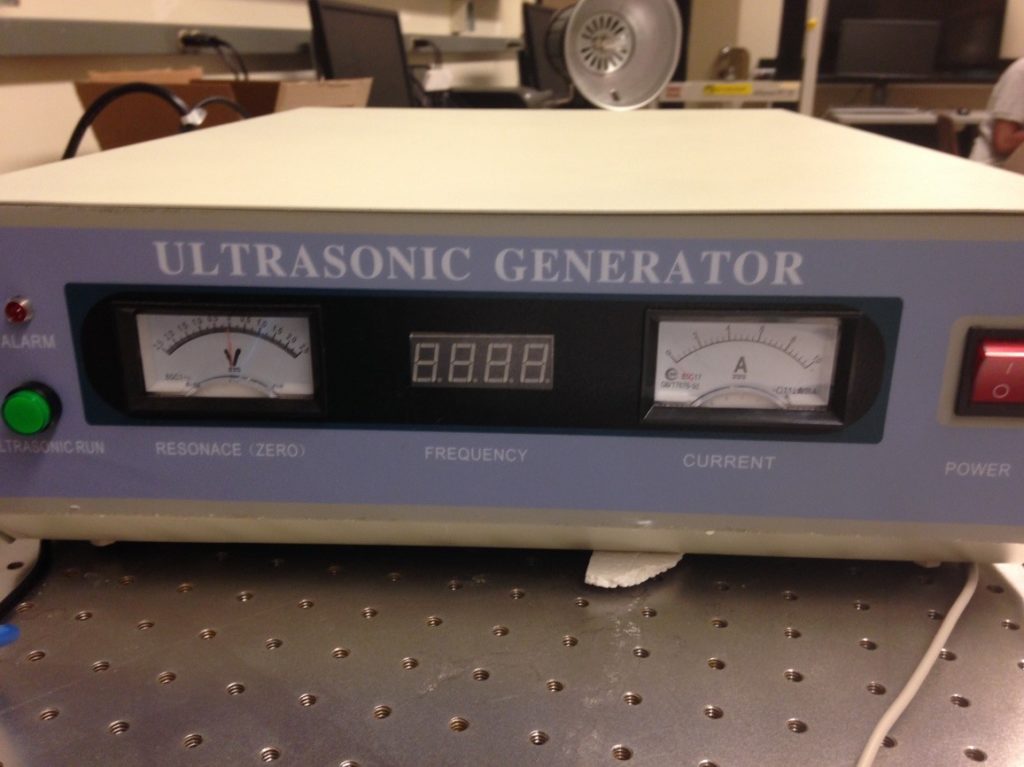

High power ultrasound generator for heating and melting 20 kHz

Current setup for SONIC IR imaging

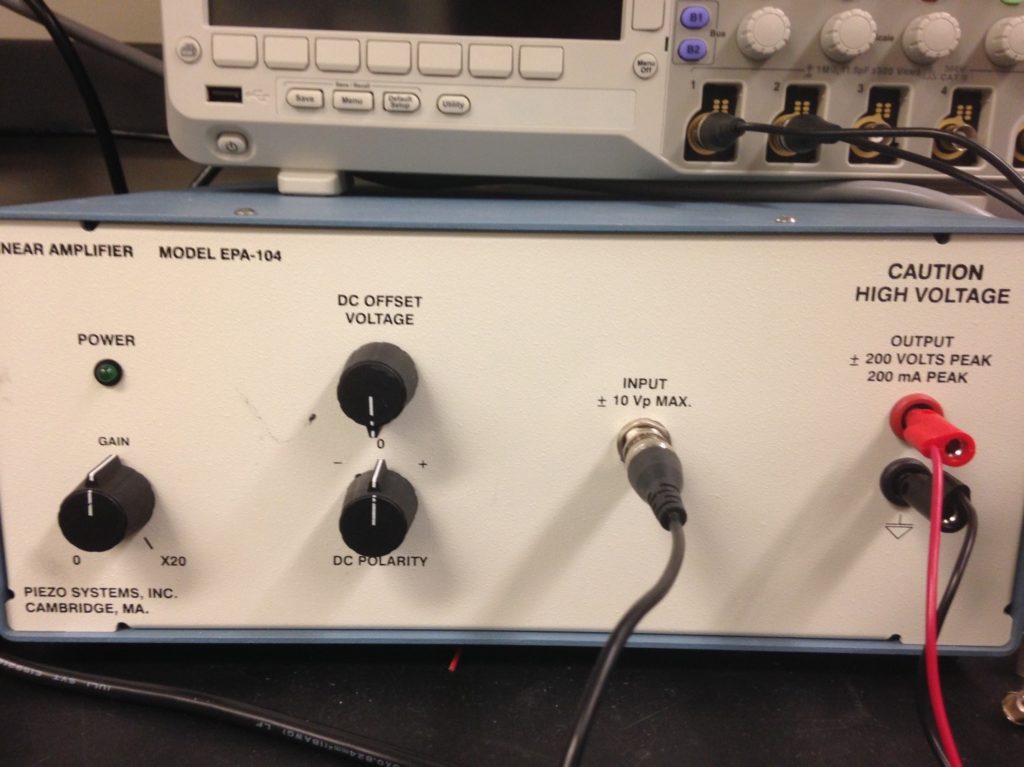

High voltage piezo acurator for sensing applications

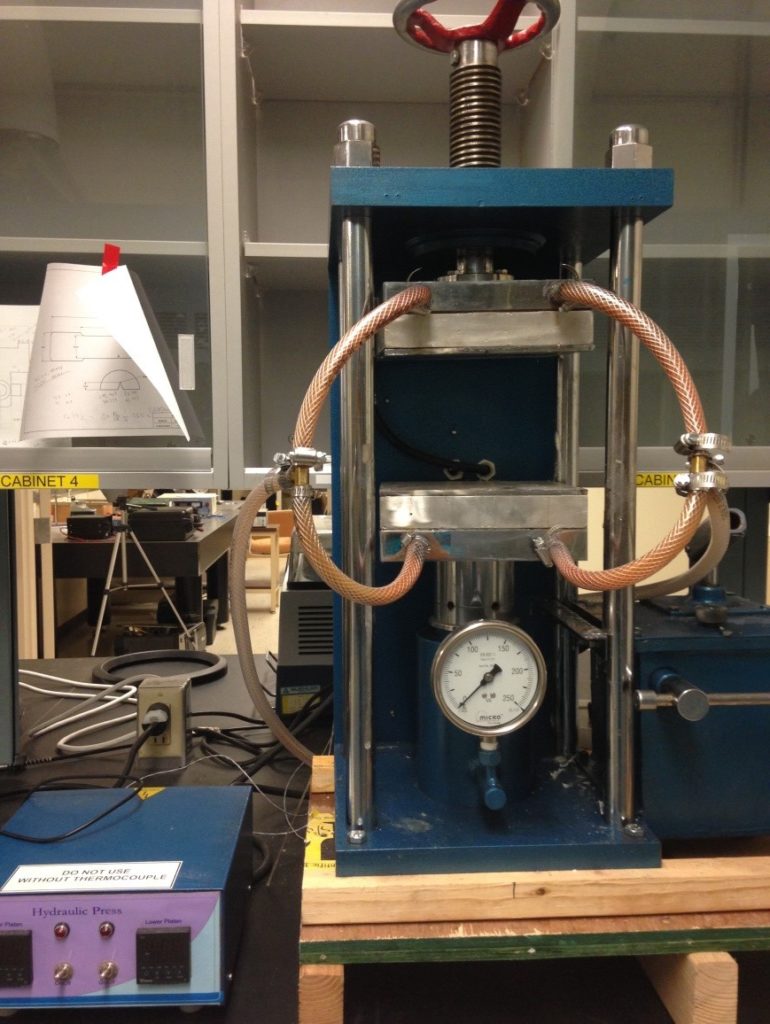

Hot pressing for manufacturing of composite laminates or other laminated system

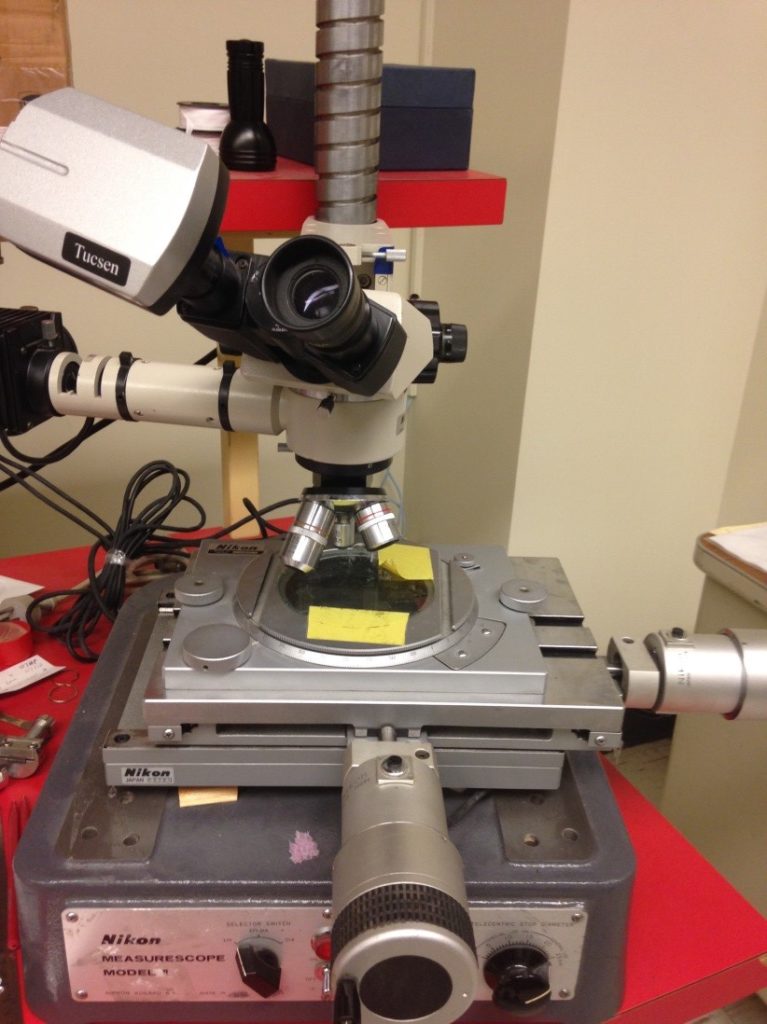

Several upright and inverted optical microscope for imaging and in situ testing

Mini-workshop for simple specimen and fixture manufacturing

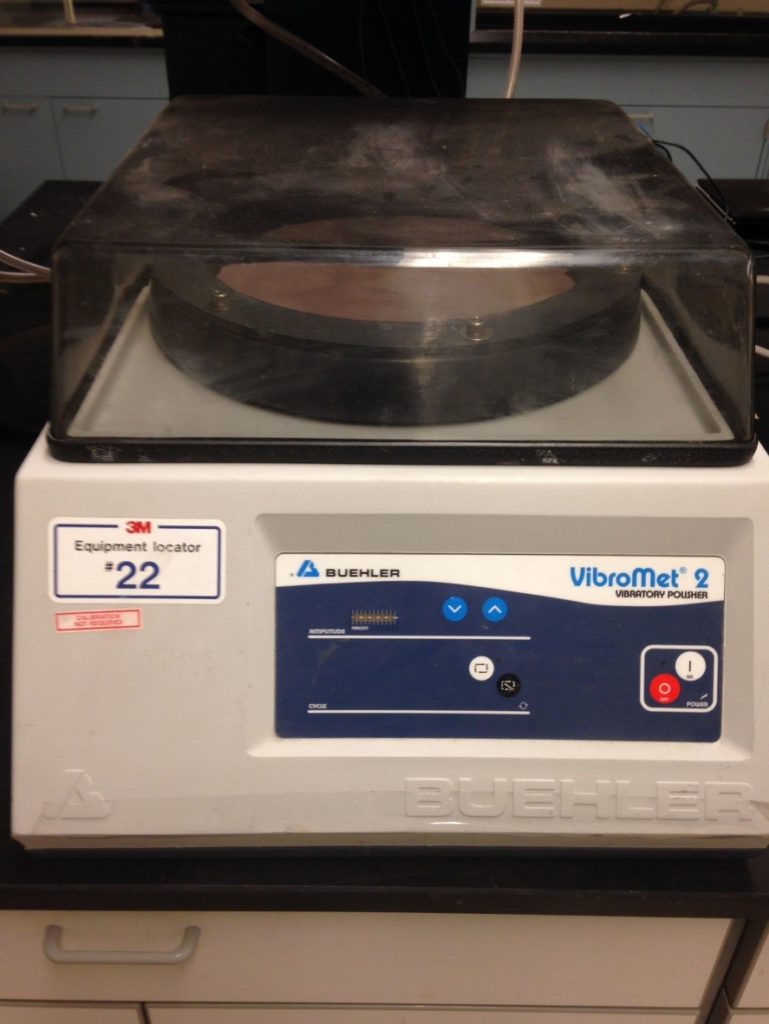

Material polishing and preparation stations

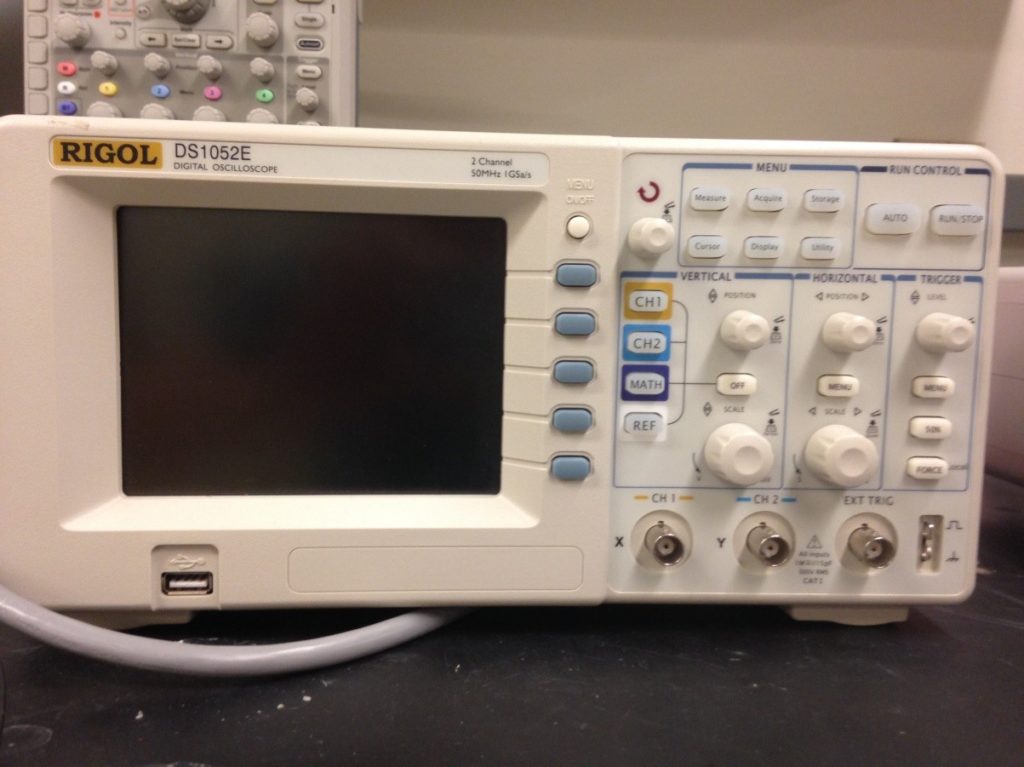

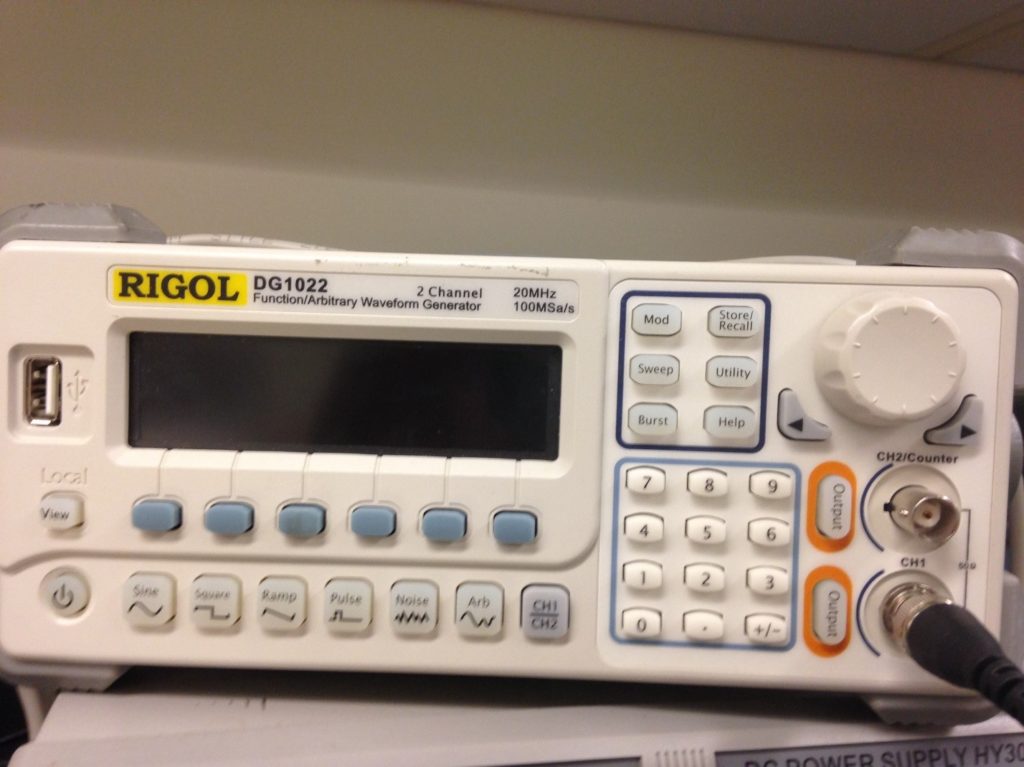

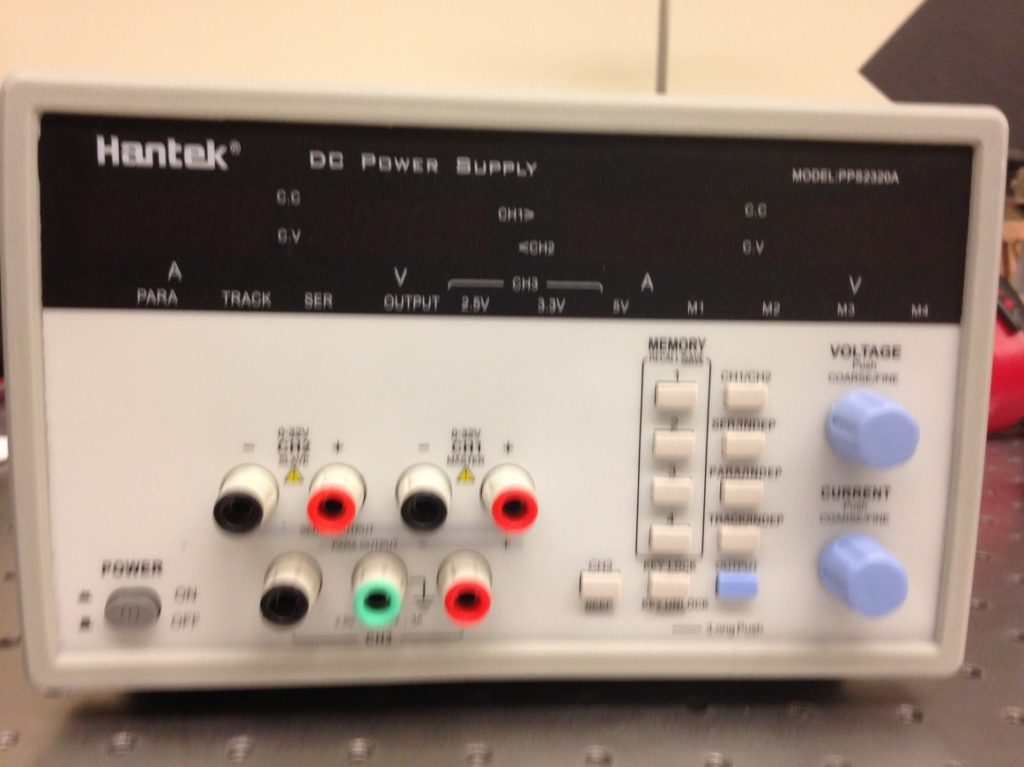

Electronic devices for sensing, generation of signals