Research

Overview

Our group is focusing on developing novel manufacturing and material processing techniques across multiple scales. We are interested in integrating disciplines of physics, chemistry, materials science, nanotechnology, and computational simulation to the new process development. We also conduct process monitoring/simulation, material characterization/modeling and property evaluation to further study the as-developed processes. Current research include: 1) electromagnetic field assisted nanomanufacturing, and process analysis, 2) laser material processing, laser matter interaction and molecular dynamics simulation, 3) additive manufacturing such as selective laser melting, fused deposition modeling, stereolithography and inkjet printing, 4) electroless plating, electrochemical co-deposition.

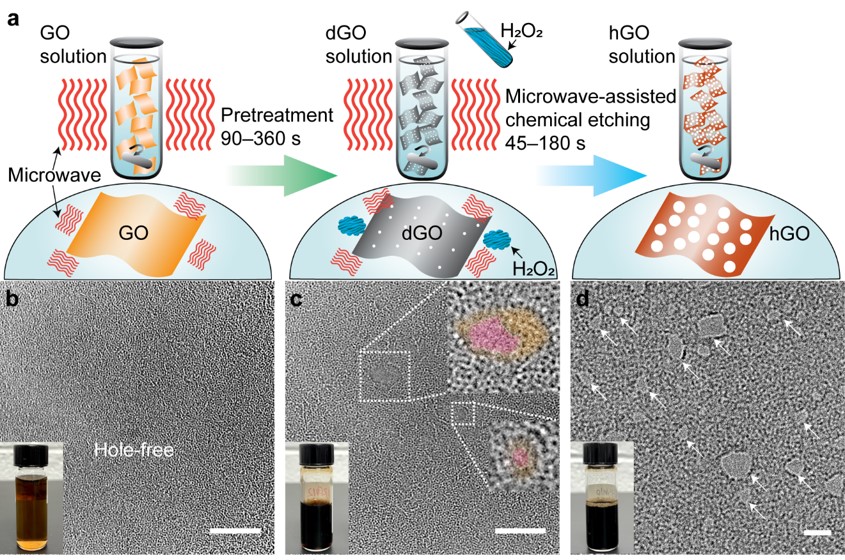

Nanomanufacturing

This research is focusing on developing novel scalable nanomanufacturing processes on basis of electromagnetic field interaction with materials. Conventional nanomanufacturing processes, such as nanosynthesis, growth, etching, doping and etc., often require aggressive chemical environment, long processing time and high temperature, due to the low heating efficiency of the conventional bulk heating. Through electromagnetic irradiation, e.g., microwave, laser, etc., the material system can be selectively heated and activated for ultra-fast processing. Fundamental studies on electromagnetic material interaction, heterogeneous heating, molecular dynamics simulation and electrochemical characterization are ongoing. The manufactured materials are seeking applications in nanocomposites, electronic devices, energy storage systems (batteries and super-capacitors), and electochemical sensors.

Example of microwave assisted chemical etching of graphene to manufacture nano-sized holes on basal plane (more information)

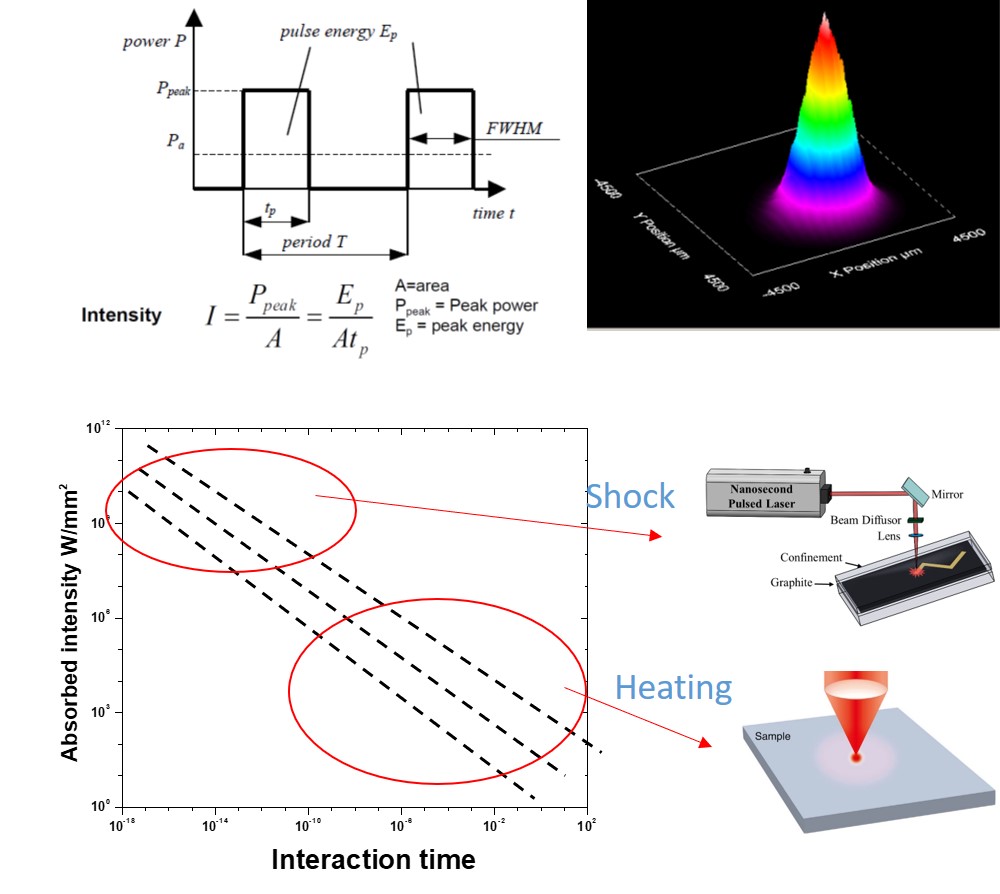

Laser material processing

This research is aiming to develop material processing techniques on basis of laser matter interaction. When short pulsed laser beam is delivered to materials, a high pressure and high temperature plasma can be created due to the energy transfer among photons, electrons and phonons. This high energy plasma can be used to process materials in a manner that is not achievable in conventional processes. Examples include confined laser shock detonation and laser shock peening. In addition, the laser beam also can be used to induce in-situ and localized heating to realize fast and selective crystallization, melting, sintering and etc. Fundamental studies on laser matter interaction, multi-physics simulation, molecular dynamics simulation and material characterization are ongoing. These processing techniques are seeking applications in extreme condition synthesis, surface property enhancing, corrosion resistance and etc.

Example of laser beam, the laser induced shock/heating effect can be used to process materials.

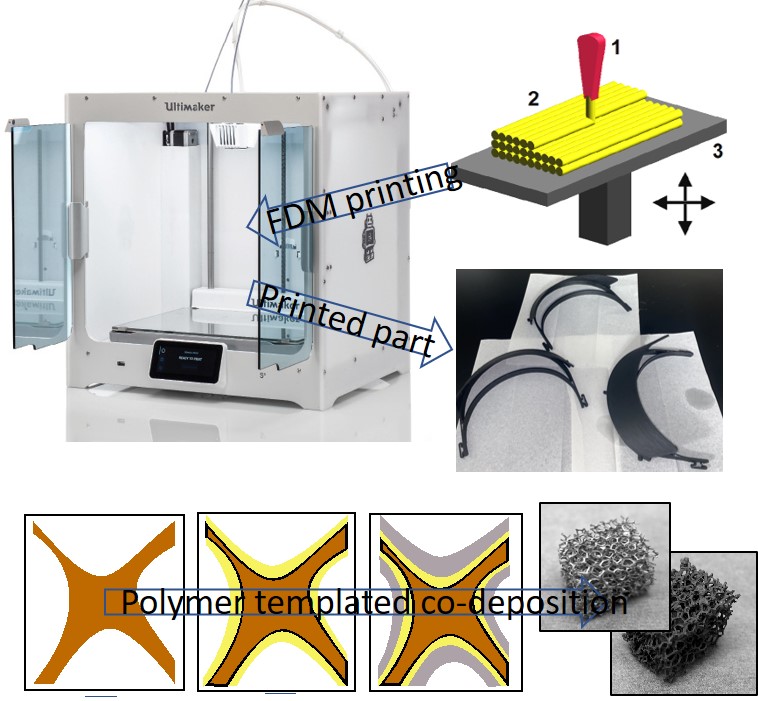

Additive Manufacturing

Additive manufacturing is an emerging manufacturing process which produces three-dimensional shape in bottom-up additive manner rather than conventional “subtractive” manner (e.g., machining). This layer by layer printing process opens up opportunities in computer aided design, material/component engineering, on-demand manufacturing and etc. Our research in this area is focusing on additive manufacturing of carbon materials and their nanocomposites. Examples include selective laser melting (SLM) of metal nanocomposites, fused deposition modeling (FDM) of polymer composites, inkjet printing of graphene, polymer templated electrochemical co-deposition, and among others. Studies on material characterization, filler-matrix interaction, manufacturing process optimization are ongoing. The manufactured parts can find applications in aerospace, automotive, biomedical, energy, and other industries.

Examples of FDM printer, printed face shields, and metal foams fabricated by polymer tempated co-deposition process.

Funding

We acknowledge all of the support that allows us to conduct our research, including from these sponsors: